In an era where digital transformation is more than just a buzzword, businesses are constantly seeking innovative ways to optimize operations and stay competitive.

One of the most groundbreaking advancements in this domain is the concept of digital twins.

Originally floated by Gartner and others as early as 2018, digital twins in procurement have seen a surge in popularity recently due to more advanced AI & GenAI models, 5G connectivity, demand for efficiency and real world success stories. Digital Twins are transforming not just manufacturing and urban planning, but also procurement and supplier management.

This blog explores how digital twins are revolutionizing these digital processes, making a compelling case for Chief Procurement Officers (CPOs) and CIOs to integrate this technology into their strategies.

What is a Digital Twin?

At its core, a digital twin is a virtual replica of a physical entity or process. It integrates real-time data and advanced analytics to mirror and simulate the real world. In manufacturing, this might mean creating a digital counterpart of a machine or a factory. In urban planning, as seen in Shanghai’s smart city initiative, it could involve a digital model of an entire city to manage infrastructure and resources efficiently.

You must have heard of, or seen flight simulators where pilots are trained and tested on various real life and also some hypothetical scenarios. In some ways, the flight simulator is a digital twin of the actual aircraft.

But how does this concept apply to digital processes like procurement or supplier management? Let’s delve into the mechanics and benefits of digital twins in these areas.

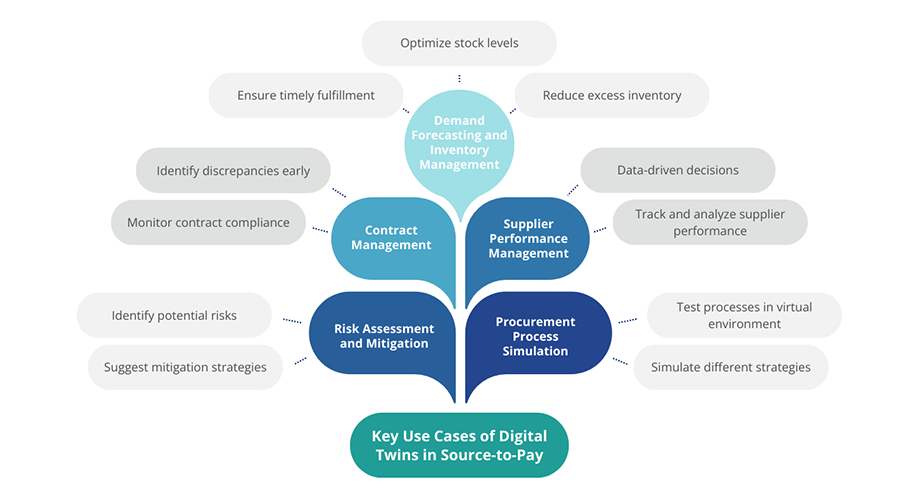

Digital twins of digital processes work by creating detailed, dynamic models of procurement workflows and supplier interactions. These models incorporate data from various sources such as ERP systems, procurement platforms, and supplier databases. Digital twins can be applied to various stages of the Source-to-Pay process, delivering tangible benefits and transforming how procurement operations are managed. Here are five key use cases:

- Supplier Performance Management: Digital twins can track and analyze supplier performance in real-time, enabling procurement teams to make data-driven decisions about supplier selection, evaluation, and improvement.

Explore Zycus’ Supplier Risk & Performance Management Software - Demand Forecasting and Inventory Management: By creating digital twins of inventory levels and demand patterns, organizations can optimize stock levels, reduce excess inventory, and ensure timely fulfillment of procurement needs.

- Contract Management: Digital twins can monitor contract compliance and performance, ensuring that all contractual obligations are met and identifying any discrepancies or potential issues early on.

Explore Zycus’ Generative AI-Powered Contract Management Software - Risk Assessment and Mitigation: By modeling the entire procurement process, digital twins can identify potential risks and vulnerabilities, such as supplier disruptions or logistical challenges, and suggest mitigation strategies to minimize impact.

- Procurement Process Simulation: Digital twins allow procurement teams to simulate and test different procurement strategies, processes, and policies in a virtual environment before implementing them in the real world. It integrates and harmonizes data from disparate sources, providing a holistic view of procurement activities. It models the entire process from need identification, through RFQ (Request for Quote) issuance, bid evaluation, contract negotiation, to supplier performance management. This reduces the risk of costly mistakes and ensures optimal process execution. Routine tasks can be automated, freeing up resources for more strategic activities.

Achieving Excellence: The Hackett Group’s Story with Zycus Generative AI

Witness The Hackett Group’s journey toward achieving excellence in procurement. This video highlights their strategic use of Zycus Generative AI to overcome obstacles and set new benchmarks in the industry.See Their Journey – Click to Watch!

Real-World Success Stories

Siemens: Pioneering Digital Twins in Supply Chain Management

Siemens, a global leader in automation and digitalization, has effectively utilized digital twins to enhance their supply chain management. By creating a virtual model of their supply chain, Siemens can simulate various sourcing scenarios, optimize supplier selection, and improve inventory management. This has led to better supplier collaboration, reduced lead times, and minimized disruptions, ultimately driving operational efficiency.

Source: Siemens Digital Industries Software

Unilever: Sustainable Sourcing with Digital Twins

Unilever, a multinational consumer goods company, has adopted digital twin technology to bolster their sustainable sourcing initiatives. By modeling their procurement processes and supplier networks, Unilever can simulate the environmental impact of their sourcing decisions, optimize resource usage, and ensure compliance with sustainability standards. This approach has helped Unilever achieve their sustainability goals while maintaining efficient procurement operations.

DHL: Optimizing Logistics and Procurement

Global logistics giant DHL has implemented digital twins to streamline their logistics and procurement processes. By simulating transportation routes, warehouse operations, and supplier interactions, DHL has enhanced supply chain visibility, improved procurement planning, and reduced transportation costs. This has resulted in more efficient and reliable supply chain management, showcasing the transformative potential of digital twins.

Benefits of Digital Twins in Procurement and Supplier Management

The adoption of digital twin technology in Source to Pay and supplier management brings numerous benefits:

- Enhanced Visibility: Digital twins provide a comprehensive, real-time view of procurement activities, enabling better tracking and management of processes.

- Improved Decision-Making: By simulating various scenarios, digital twins help procurement teams make informed decisions, optimizing sourcing strategies and supplier interactions.

- Proactive Risk Management: Predictive analytics identify potential risks and enable proactive mitigation, reducing disruptions and ensuring smooth operations.

- Operational Efficiency: Digital twins streamline workflows, automate routine tasks, and eliminate inefficiencies, leading to significant time and cost savings.

- Strategic Planning: Scenario planning capabilities facilitate long-term strategic planning, helping organizations navigate uncertainties and stay ahead of the competition.

Is Digital Twin Technology Right for Your Organization?

While the benefits of digital twins are clear, not every organization may be ready to adopt this technology. Here are some factors to consider when assessing your organization’s readiness:

- Digital Maturity: Organizations with a high level of digital maturity, including robust data infrastructure and advanced analytics capabilities, are better positioned to implement and benefit from digital twins.

- Data Availability and Quality: Digital twins rely on accurate, real-time data from various sources. Ensuring that your organization has access to high-quality data is crucial for the success of digital twin initiatives.

- Scalability: Consider whether your organization has the necessary resources and scalability to support the deployment and maintenance of digital twin technology.

- Strategic Alignment: Ensure that the adoption of digital twins aligns with your organization’s overall strategic goals and objectives. This technology should support and enhance your procurement strategy, not create additional complexity.

Implementing Digital Twins: Best Practices

For CPOs and CIOs looking to harness the power of digital twins in procurement and supplier management, here are some best practices:

- Start Small and Scale: Begin with a pilot project to demonstrate the value of digital twins. Once successful, gradually scale the implementation across the organization.

- Invest in Data Integration: Ensure seamless integration of data from various sources to create a comprehensive digital twin. Invest in robust data management and integration tools.

- Leverage Advanced Analytics: Utilize machine learning and advanced analytics to derive meaningful insights from the digital twin. This will enhance predictive capabilities and decision-making.

- Collaborate with Technology Partners: Partner with reputable technology providers who specialize in digital twin solutions. Their expertise and support will be crucial for a successful implementation.

- Focus on Change Management: Implementing digital twins requires a cultural shift within the organization. Invest in change management initiatives to ensure smooth adoption and alignment with business goals.

Conclusion

Digital twins represent a transformative leap forward in the realm of procurement and supplier management. By creating virtual replicas of these digital processes, organizations can achieve unprecedented levels of visibility, efficiency, and strategic insight. For CPOs and CIOs, embracing digital twin technology is not just a trend but a strategic imperative that can drive significant value and competitive advantage. As the digital landscape continues to evolve, those who harness the power of digital twins will be well-positioned to lead their organizations into the future.

Explore the potential to explore the potential of digital twins, and take the first step towards revolutionizing your procurement and supplier management processes today. The future is digital, and the future is now.

Related Reads:

- Simplifying the Source-to-Pay Workflow: A Comprehensive Guide

- How Source-to-Pay Applications Supercharge Your Bottom Line: Fuel Your Profits

- Unleash Strategic Roadmap for Source-to-Pay Technology 2024

- Unlock Source-to-Pay Optimization: Benefits & Best Practices

- Case Study: Delta Air Lines Powers Procurement with Zycus’ S2P Solution

- Case Study: 4 Asia-Pacific Case Studies of Successful Procurement Transformation- Zycus

- Beyond the Hype: A CPO’s Guide to Selecting the Right Multi-Agent GenAI for Procurement

- Harnessing the Power of Multi-Agent Generative AI in Procurement Software: The Future of Intake Management Solutions