What is a Supplier Network?

An online platform or digital ecosystem that links buyers and suppliers for the purpose of conducting procurement activities is referred to as a supplier network. These platforms streamline and expedite the exchange of goods, services, and information between enterprises.

In the context of procurement, supply chain network frequently use technology to improve communication, automate processes, and increase visibility over the course of the procurement lifecycle.

What is a ‘Supplier’ in a supply chain?

A person, business, or organization that delivers goods, services, or raw materials to another entity as part of the manufacturing or distribution process is referred to as a ‘Supplier’ in a supply chain. Suppliers are essential to the entire operation of a supply chain, which is a web of connected activities and entities that work together to transport goods from their point of origin to final consumers.

Depending on the complexity of the good or service and the industry, suppliers can be found at various places throughout the supply chain. They could offer raw materials, components & parts, finished goods, services, technology and software, and much more. Read here: 8 Unique Phases of Supplier Lifecycle Management

The intricacy and level of cooperation in a company’s relationship with its suppliers might vary. To ensure quality and innovation, some businesses keep tight relationships with their suppliers and include them early in the product creation process. Others might engage in more transactional relationships where cost and efficiency are the main priorities.

To avoid delays, regulate costs, maintain product quality, and ensure a seamless flow of goods and services, effective supplier management is essential. For fostering fruitful partnerships and ensuring that the entire supply chain operates well, organizations frequently participate in supplier appraisal, negotiation, and performance monitoring.

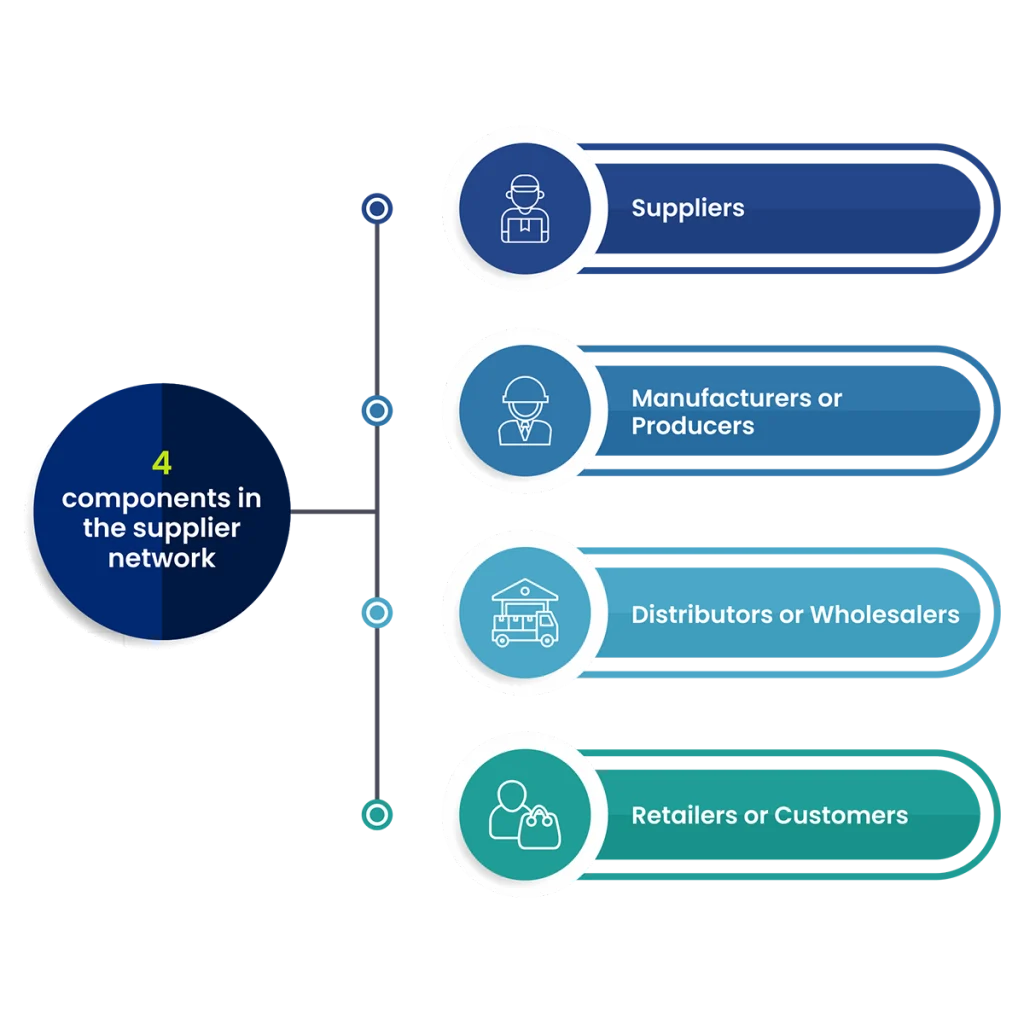

What are the 4 components in the supplier network?

A supply chain network typically consists of four major parts or sections, which work together to build the network’s structure. Together, these elements support the smooth movement of commodities, services, information, and value along the whole supply chain. These are the four elements:

Suppliers: Suppliers are entities that provide the commodities, materials, services, or components needed for the creation of a finished product. They are the first link in the supply chain and have a major impact on the cost, availability, and quality of inputs.

Manufacturers or Producers: Manufacturers turn the raw materials, components, or services supplied by suppliers into completed goods. Through diverse production techniques, they increase the value of these inputs. To make a finished product, manufacturers may also put together numerous components from diverse suppliers.

Distributors or Wholesalers: Manufacturers and merchants are connected through distributors. They buy big amounts of merchandise from producers and divide it up into smaller bits for resale to merchants or final customers. Distributors aid in the effective distribution of goods to various markets.

Retailers or Customers: The businesses that sell goods directly to consumers are known as retailers. They could consist of physical storefronts, internet merchants, and other sales channels. Retailers interact directly with customers and are essential to marketing, providing excellent customer service, and ensuring that products are distributed to the right customers.

Within the network of the supply chain, these four elements are interrelated and dependent on one another. It is up to these elements to work together, coordinate, and communicate for the network to function effectively. The precise and prompt exchange of information regarding demand, inventory levels, production plans, and market trends is another crucial component of the supply chain’s efficiency and responsiveness.

It’s essential for one to understand that based on the sector, the complexity of the product, and the distribution routes, various supply chains may have additional components or variations. The key parts of suppliers, manufacturers, distributors, and retailers continue to play a crucial role in the overall design and operation of most supplier networks.

Benefits of Supplier Network for Suppliers and Buyers

Benefits for Suppliers:

Increased Visibility and Reach

Being part of a supplier network exposes suppliers to a broader range of potential customers, including large corporations, which they might not have reached otherwise. This can lead to increased business opportunities and revenue.

Stable demand

Supplier networks frequently offer suppliers a consistent flow of orders and contracts, lowering the uncertainty brought on by changes in demand. Suppliers can more efficiently plan production and resource allocation due to this steadiness.

Reduced marketing costs

Due to the network’s built-in audience for their products or services, suppliers can lower their marketing and sales expenses. This can lead to cost savings and more efficient business operations.

Collaborative innovation

Supplier networks frequently encourage participant engagement and knowledge sharing. Both suppliers and customers may gain from innovation and the creation of new products, services, or processes as a result. Also, read Demystifying the Supplier Management Process for Success

Efficient Inventory Management

Suppliers can manage their inventory more effectively and cut back on excess inventory and related carrying costs by having better visibility into demand projections and customer preferences.

Access to Resources

It’s possible for suppliers to obtain access to tools, expertise, or technology they can use to boost their productivity, quality, and efficiency—all of which will make them more competitive.

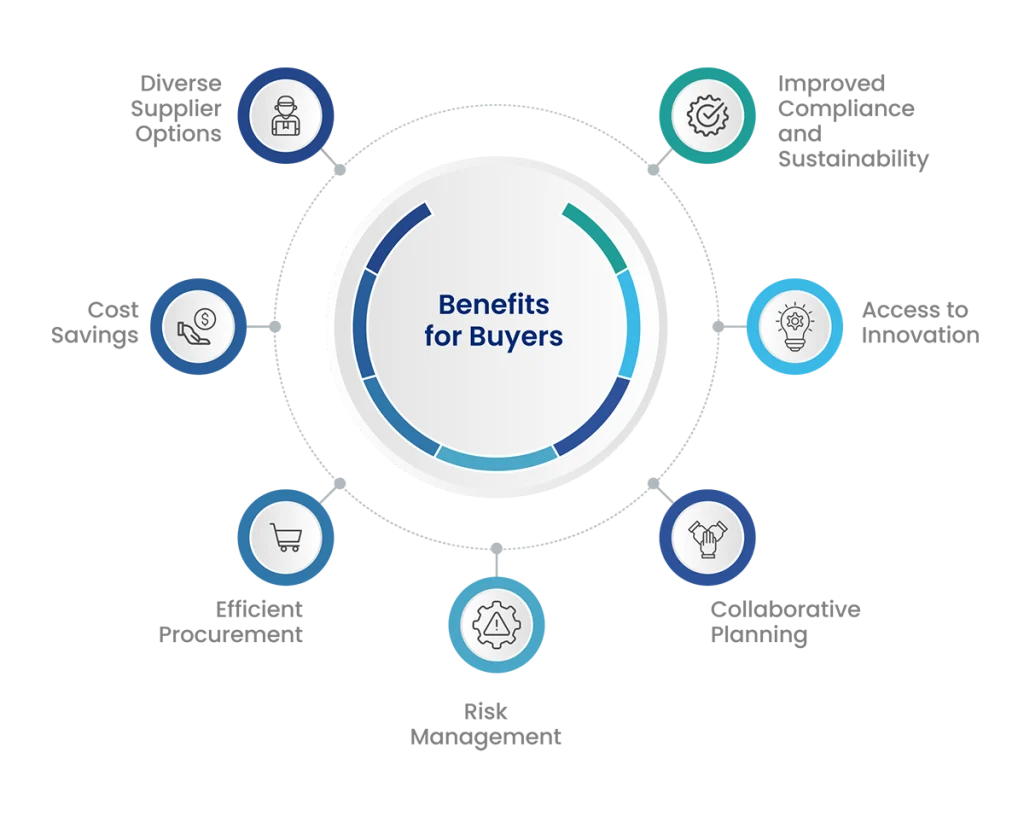

Benefits for Buyers:

Diverse Supplier Options

With more suppliers available to them through a supplier network, buyers may choose the ones that best meet their requirements in terms of quality, cost, and capabilities.

Cost Savings

Improved pricing for customers may result from more competition among suppliers inside the network. Due to the transparency and market forces at work, buyers are able to negotiate better terms and pricing.

Efficient Procurement

Supplier networks frequently offer e-procurement platforms and automated sourcing as well as other tools and technology that simplify the procurement process. As a result, purchase procedures become quicker, more precise, and less resource intensive.

Risk Management

The risk of supply chain interruptions can be minimized by having a broad supplier base within a network. Customers can simply switch to alternative sources if one supplier has problems, maintaining supply continuity.

Collaborative Planning

Collaboration between buyers and suppliers is made possible by supply chain network in terms of demand forecasting, inventory management, and production scheduling. Efficiency increases, and lead times are reduced because of this synchronization.

Access to Innovation

Suppliers with specialized knowledge and creative ideas are frequently found in supplier networks. To stay current with market trends and include cutting-edge goods or technologies in their offerings, buyers might make use of this expertise.

Improved Compliance and Sustainability

Networks of suppliers can make it easier to adhere to sustainability and industry standards. Suppliers that fit their ethical and environmental standards and are in line with their beliefs can be chosen by buyers.

In conclusion, supplier networks provide both buyers and sellers with a number of advantages, including better access to innovation, cost reductions, efficiency gains, risk mitigation, and enhanced visibility. These benefits aid in fostering stronger business relationships and raising market competition.

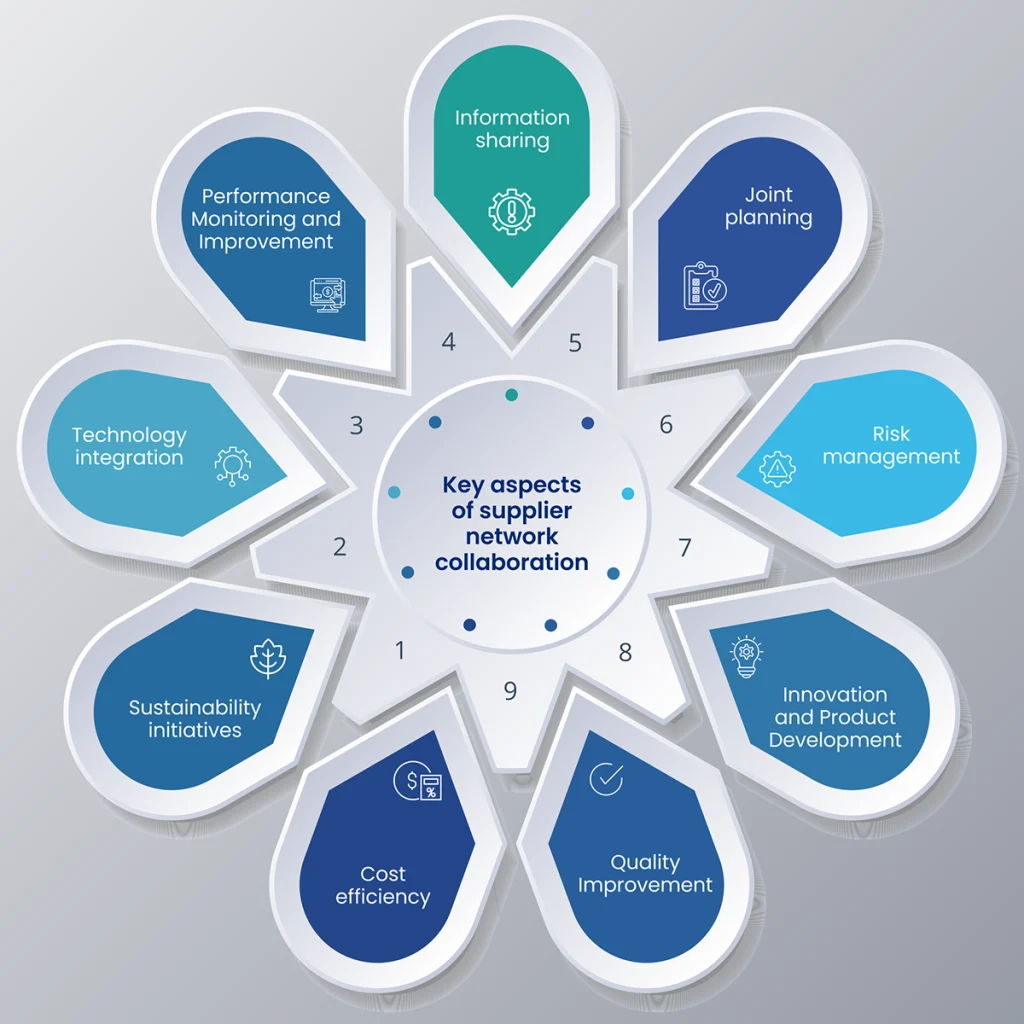

What is supplier network collaboration?

Supplier network collaboration refers to the strategic and cooperative relationship between a company and its suppliers within a supply chain network. To accomplish shared objectives and raise the effectiveness, efficiency, and competitiveness of the whole supply chain, this collaboration entails exchanging knowledge, resources, and experience.

Read our blog on: Supplier Collaboration Networks: A Roadmap to Unlocking Synergy in Procurement

Key aspects of supplier network collaboration include:

Information sharing: Businesses and their suppliers exchange pertinent data on demand projections, production plans, inventory levels, quality standards, and market trends. Better planning and coordination are made possible by this real-time information transmission, which lowers the possibility of overstocking or stock outs.

Joint planning: Cooperative planning entails working together to create production timetables, order schedules, and inventory management plans that are in line with consumer demand. This helps reduce production interruptions and maximize resource use.

Risk management: Through collaborative interactions, both parties are able to jointly evaluate and reduce risks. This entails spotting potential supply chain interruptions, such as geopolitical problems, natural disasters, or changes in consumer preferences, and creating backup plans to deal with them.

Also read: A Comprehensive Guide to Supplier Risk Management

Innovation and Product Development: Suppliers can frequently be excellent sources of creativity and fresh concepts for new products. Early supplier involvement in product development can result in more functional and well-designed products with shorter time to market.

Quality Improvement: Close cooperation between businesses and their suppliers enables them to jointly set and adhere to high standards for quality. To improve overall product quality and customer happiness, suppliers can offer comments on how well their products operate as well as improvement suggestions.

Cost efficiency: By working together to streamline operations, cut waste, and increase supply chain efficiency, supplier networks can achieve cost savings. Better pricing terms and agreements can also be reached through collaborative bargaining.

Sustainability initiatives: Collaboration is possible in sustainability initiatives which includes promoting ethical sourcing methods and lowering environmental impact. Suppliers can work together to achieve environmental goals, such as lowering carbon emissions or producing less waste.

Technology integration: To improve communication and data exchange during collaborative projects, technology systems may be integrated. This may involve utilizing shared platforms for demand forecasting, inventory management, and order management.

Performance Monitoring and Improvement: Collaboration enables ongoing supplier performance monitoring and the detection of problem areas. Metrics like on-time delivery, lead times, and product quality can be a part of this.

Trust, open communication, and transparency are necessary for successful supplier network collaboration between all participants. It frequently entails going past transactional connections and adopting a more long-term, strategic partnership approach. The supply chain resilience, customer happiness, and competitive advantage of businesses who invest in supplier network collaboration tend to all be improved.

Why is supplier network important?

Supplier networks are essential for businesses because they improve supply chain efficiency and effectiveness. These networks provide efficient material movement and minimal delays by streamlining procedures. As suppliers compete to offer the best pricing and terms, this efficiency results in cost reductions for customers. Additionally, diversified supplier options reduce the risk of disruptions, providing business continuity even in the face of unexpected events.

Supplier networks also foster innovation and teamwork. These online forums promote discussion and the sharing of best practices, which leads to advancements in both products and procedures. These networks give users access to specialized knowledge, allowing sellers to improve their products. Better decisions could be made because to the transparency and visibility they provide since they provide thorough understandings of supply chain dynamics.

Supplier networks also promote legal compliance and sustainable business practices. They make it easier to follow moral and professional standards, enabling customers to select suppliers that share their commitment to sustainability and social responsibility. Within these networks, long-term collaborations are fostered as companies establish connections based on mutual respect and shared goals.

In the end, supplier networks are now essential to supply chain management, allowing companies to maintain their competitiveness, agility, and customer-centricity. Discover how Zycus can improve your supplier management process, book a demo with our experts.

Related Reads

- Things You should Know about your Supplier Network!

- Building Success Through a Solid Supplier Management Framework

- Brochure- Supplier Management

- Embracing Automation for Enhanced Connectivity, Supply Network Relationship and Role of Automation

- Zycus Supplier Network Management Software

- eGuide- The Ins and Outs of Supplier Networks

- Whitepaper- Essential Components of a World-Class Supplier Performance Management Tool : A MENA Perspective