Delays caused by incorrect supplier contact details or pricing errors are just a glimpse of how poor data management can throw a wrench into supply chain operations. Embedding accuracy, consistency, and reliability in Supplier Data Integrity not only streamlines communication and transactions but also serves as an operational backbone in dynamic market conditions. This article explores the pivotal role of high-quality data, shedding light on strategies that fortify the pillars of supplier data management to safeguard operational continuity and fiscal health.

Understanding Data Integrity in Supplier Data Management

Data integrity is the cornerstone of effective supplier data management (SDM). It ensures the accuracy, consistency, and reliability of supplier-related information throughout its lifecycle. By maintaining high standards of data integrity, businesses can ensure their supplier databases truly reflect real-world scenarios, thereby preventing any discrepancies that might affect operations or decisions.

For instance, consider a scenario where inaccurate supplier contact details might delay urgent communications, leading to potential disruptions in supply chains. Incorrect pricing information recorded in the system could result in financial discrepancies during procurement. Such issues underline the critical nature of data integrity in managing supplier information effectively.

Key components ensuring data integrity include:

- Accuracy: Data should correctly represent true values.

- Consistency: Data should be consistent within itself across different databases or systems.

- Reliability: Data should be sufficiently correct and reliable for its intended use.

Impact of Data Integrity on Supplier Data Management

The role of data integrity extends beyond mere record-keeping; it is inherently linked to the operational success of an organization. Here’s how robust data integrity in supplier data management impacts various business dimensions:

- Operational Efficiency: Consistent and accurate data allow for smoother operational workflows, such as timely order placements and inventory management.

- Compliance and Auditing: Reliable data is critical in adhering to regulatory requirements, particularly in heavily regulated industries. For example, in the pharmaceuticals sector, accurate supplier data is essential for compliance with safety standards and to prevent risks associated with supply chain lapses.

- Strategic Planning: With dependable data, companies can forecast future needs more accurately, plan for demand fluctuations, and make informed strategic decisions.

How Data Integrity Improves Supplier Onboarding

Integrating a new supplier into an existing system can be complex. By emphasizing data integrity, businesses can enhance the efficiency of the onboarding process. Accurate and reliable data ensures:

- Swift Validation: Quick and accurate verification of supplier credentials and capabilities.

- Smooth Integration: Easier integration into procurement processes and systems with reduced chances of error.

- Trust and Compliance: New suppliers feel confident in the business’s data handling practices, fostering trust and adherence to compliance requirements from the start.

The advantages of robust data integrity include reduced time-to-market for new collaborations and products, as well as improved supplier satisfaction and relationship management.

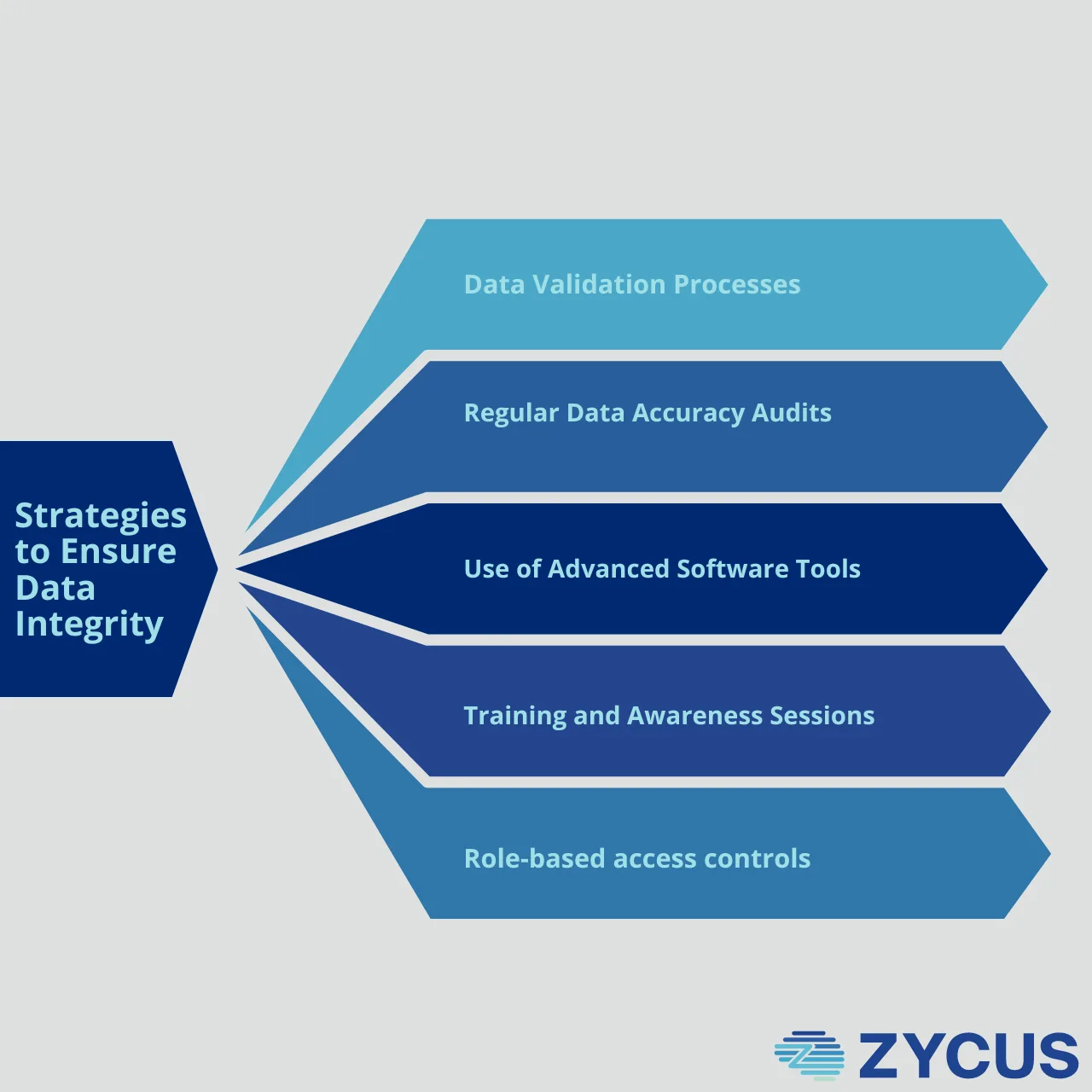

Strategies to Ensure Data Integrity in Supplier Data Management

Maintaining impeccable data integrity requires a proactive approach. Here are some strategies businesses can implement:

1. Data Validation Processes:

- Implement automated tools to check data accuracy and consistency as it’s entered.

- Set up alerts for any discrepancies noted during data entry.

2. Regular Audits:

- Schedule periodic audits to review and verify the accuracy of the supplier data.

- Use these audits to check for compliance with company policies and industry regulations.

Also Read: The Importance of Effective Supplier Audit Management

3. Use of Advanced Software Tools:

- Employ sophisticated data management solutions that feature capabilities for real-time data correction, duplication checks, and historical data tracking.

- Ensure backup systems are in place to recover data in case of loss or corruption.

4. Training and Awareness:

- Conduct regular training sessions to educate employees about the importance of data integrity.

- Share best practices and updates in data management protocols.

5. Controlled Access:

- Implement role-based access controls to ensure that only authorized personnel have access to sensitive supplier data.

- Regularly review and adjust access privileges to mitigate the risk of unauthorized data manipulation.

Implementing these strategies not only safeguards data integrity but also enhances overall business efficiency, reputation, and supplier relationships.

Elevating Business Through Meticulous Supplier Data Management

In an era where operational efficiency and compliance cannot be compromised, upholding data integrity within supplier data management (SDM) isn’t just a good practice—it’s a critical necessity. By embedding rigorous data validation processes, conducting regular audits, leveraging advanced technological tools in supplier compliance management, promoting awareness through training, and controlling access to data, businesses can shield themselves against inaccuracies that threaten operational stability and strategic decisions.

These practicable steps do not just protect data integrity; they amplify the operational capabilities, compliance adherence, and strategic foresight of businesses. Compliance with regulatory requirements becomes seamless and more reliable, especially in highly regulated industries, thus circumventing potential legal and logistical setbacks. Furthermore, by ensuring the accuracy, consistency, and reliability of supplier-related data, companies empower themselves to predict market needs, adjust to demand fluctuations, and strategically pivot with precision.

Implementing a robust data integrity framework smoothens the pathway for new supplier onboarding, fostering a climate of trust and compliance from the outset. This, in turn, translates to quicker integration and deployment periods, enhancing supplier relationships and satisfaction, which is essential for sustained business growth and innovation.

To truly understand how robust data integrity strategies can transform your supplier data management processes and to see these principles in action, schedule a demo with us today. Explore how you can not only meet but exceed the expectations in your supply chain operations, ensuring your business remains competitive and compliant in the dynamic global market.

Related Reads:

- ProcureNxt Unveils the Future of Procurement: A Deep Dive into Zycus’ GenAI Platform

- Solution: Supplier Management Software

- The GenAI-Powered Future of S2P: Predictions for 2025 and Beyond

- Web Story: Generative AI in Supply Chain Management

- eBook: Master the Generative AI Revolution in Procurement

- Generative AI: The Perfect Storm of Opportunity in 2024

- On-Demand Webinar: Revolutionizing Procurement: How Generative AI Can Set Procurement Leaders up for Success

- Utilize the Power of Generative AI in Spend Management: A Comprehensive Guide